Customers only become long-term partners when we can do it better than our competitors. This places us successfully on the market for optical, electrical and catalytic performance coatings.

The best preconditions for this come from our decades of experience in coating as well as with the nanotechnology used in the sol-gel process.

Our range of products

According to your personal wishes, we apply customised coatings according to the highest technical requirements on:

lamps;

halogen lamps and sodium vapour lamps;

glass containers for equipment manufacturing;

glass and plastic with electrically conductive layers (please see PDF product information)

glass panes.

Lamps are coated with

absorbent and pigment-based layers (e.g. blue lamps increase colour temperature)

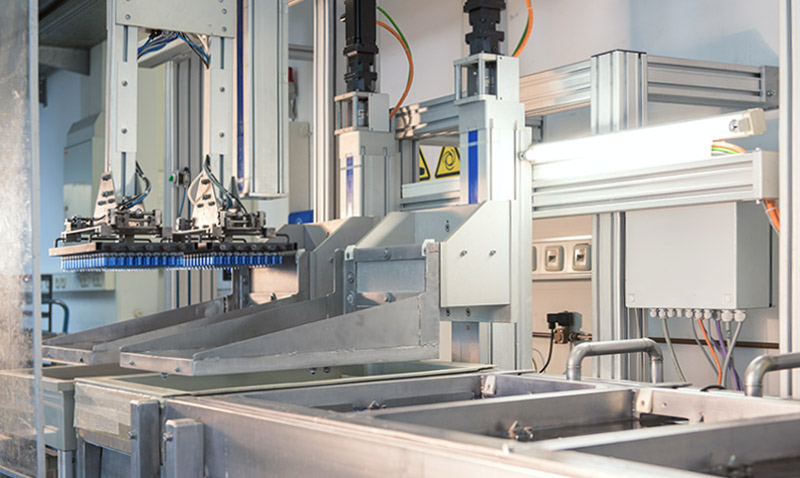

and special coating solutions. The coatings can be structured and optically characterised. Large-scale production is possible.

interference coatings, also in large-scale production.

electrically conductive layers (“heating coating”).

We develop the right functional coating solutions, incl. electrical characterisation, and create custom products as well as perform module development.

anti-reflection (AR) coatings.

We coat halogen and sodium vapour lamps for

blocking UV radiation:

To do this, we use functional pigments, develop the chemical specification for the coating solution, choose the suitable matrix materials and take care of characterisation and durability of the protective effect against UV radiation.

We develop coating solutions with required characteristics that can be reproduced.

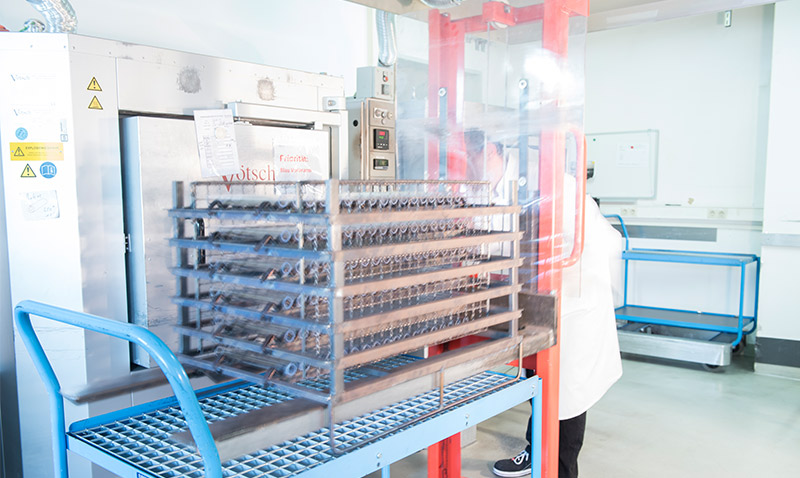

We have the capacity to manufacture on a large scale.

colour-intensive lighting.

correcting colour values used in the perfect presentation of goods.

Coating glass containers for equipment manufacturing is done by

UV blockers

electrostatically dissipative layers

heated layers

We apply functional coatings

on glass bodies with:

UV blockers

heating layers

electrically conductive tin oxide coating

on glass and plastic with lectrically conductive polymer coatings

with anti-static function to dissipate electrical charges (explosion protection)

with sensory function to forward measurement data

Coating of glass for viewing panes used for

lamp construction

blocking UV radiation

anti-reflection

More information

Here, you can find our downloads, certificates, and important links.

Get in touch.

We’ll be glad to help you!

Glas-Plus Beschichtungs GmbH & Co. KG

Galileo-Galilei-Str. 28, 55129 Mainz, Germany

Fon: +49 (06131) 90833-60

Cellphone: +49 1517 0306255

Email: info@glas-plus.de